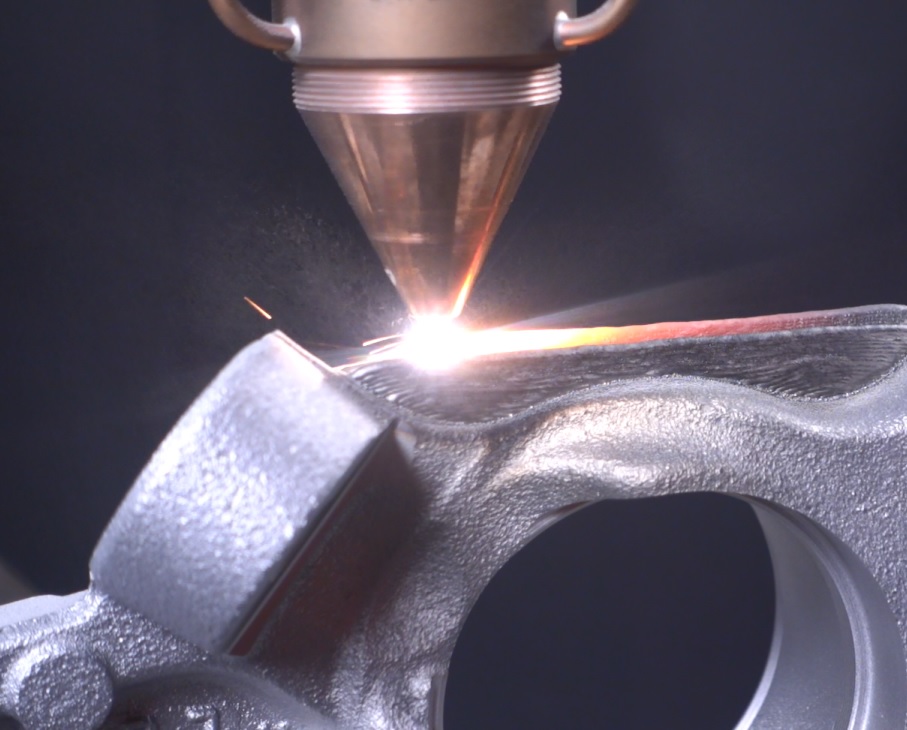

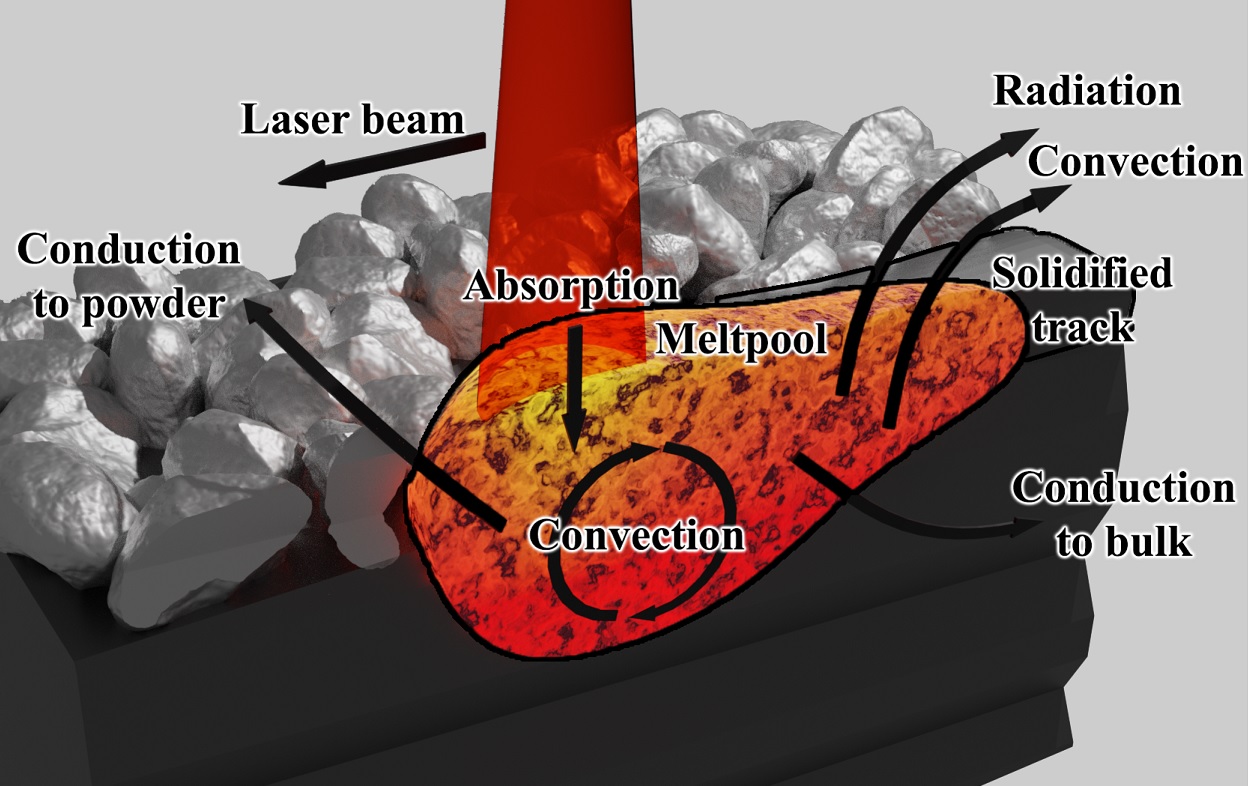

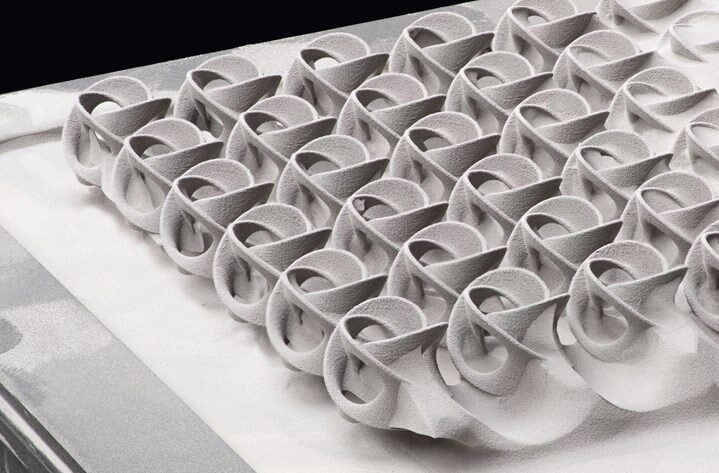

Powder Bed Fusion (PBF) is an additive manufacturing technique that uses a heat source, typically a laser or electron beam, to fuse powder particles layer-by-layer, forming a solid part. PBF enables the production of geometrically complex parts that would be difficult or impossible to produce with traditional manufacturing techniques.

One of the main advantages of PBF is its flexibility in terms of materials and technology. PBF can be used with a wide range of materials, including metals, polymers, and ceramics, and can be applied using several different techniques, including Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Energy Deposition (DED).

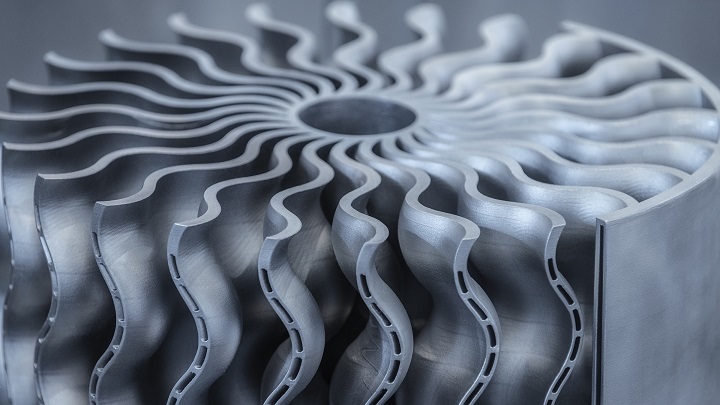

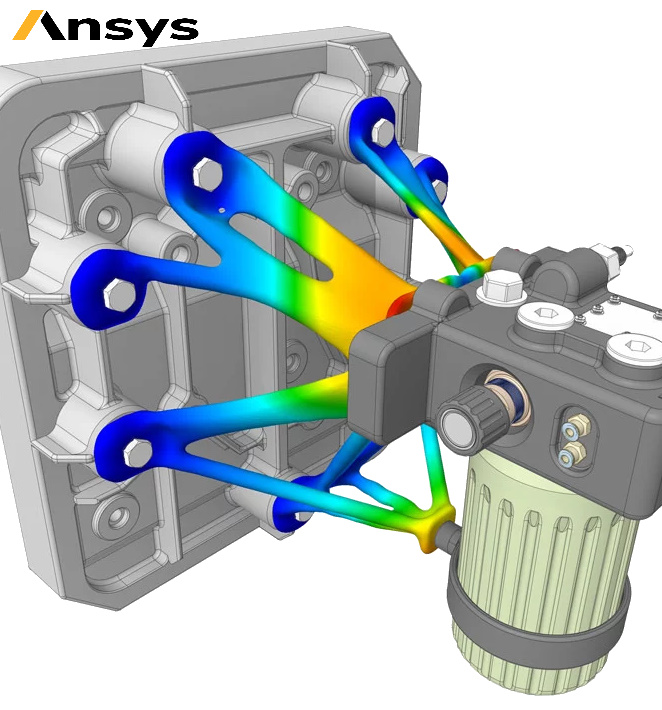

Furthermore, PBF offers a high degree of design freedom, as complex geometries can be produced without the need for complex tooling or machining processes. This allows manufacturers to create highly customized and intricate parts that would be difficult or impossible to produce with traditional manufacturing techniques.